This is the one that started it all for me and illuminated lightsabers. This is the Obi Wan Kenobi Episode IV "A New Hope" lightsaber. The offerings from Master Replicas and Hasbro have that extra fat windvane piece that is pretty much meh.

So I decided I needed to make myself one out of the most accurate reproductions of the vintage parts, or the vintage parts themselves. I set out to make the most screen accurate ANH Obi saber I could, and here is my build log for it.

I found a section of aluminum tube that I shaved down on the lathe to secure the blade tube to the inside of a RussRep emitter, it's super snug and tight, and with a few set screws on the inside of the emitter, going into a custom machined base on the inside of the polycarbonate tube, it should be sturdy enough to not move much.

Here we go!

The small aluminum tube is some scrap I had that BARELY fits the light tube. I had to shave it down to fit inside the inner section of the emitter.

Here's the spacer on the light tube. I will have to trim off the excess light tube, and replace the plastic LED base on the inside with an aluminum base I can screw into.

This shot is the saber at the G4TV Hoth Ice Bar... Which was a lot of fun.

Next up, with the convention past me, I can do a little work tonight on my blade, I think I finally finished this step up. I had to shorten my blade a couple inches, and then I needed to finish my plug.

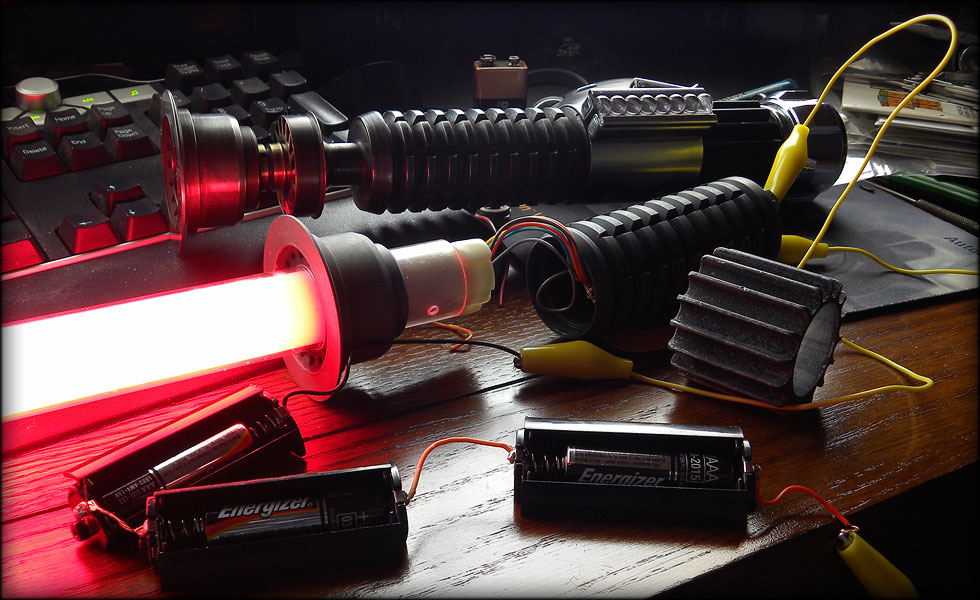

Here's the saber lit. I know I have the wrong color, but this is a broken Vader force FX I scavenged just to see if the parts would fit. The controller board is sitting in the grenade, and instead of 3 AA batteries, I am powering it with 3 AAA batteries. These will fit stacked inside the hollow aluminum booster.

I have a good idea how to attach the emitter to the grenade solidly enough that it won't be flimsy, and still use the "correct" windvane neck from Russ. Wiring will have to be changed out a bit to fit inside the neck, but it's doable. Meaning I will have to relocate the clash sensor, and with those two wires not going through the neck, I can feed the rest through a drilled out 5/8 threaded rod.

I have it worked out pretty much except for the pommel end, and am still sketching that out, but I think that's easier to solve than the emitter.

What I am talking about is more like creating an anchoring piece of metal that really solidifies in the emitter... kind of like this...

The aluminum plug will really help solidify the blade to the emitter.. I will need to trim out some of the diffuser element from the blade, and thread the plug for 3/8 threaded rod.

Here I have it fit together, and see my plug is too long, and has no recess to let the emitter end of the windvane neck to sit inside. I will shorten the plug and lathe out a recess for the neck section.

Here is the key to the project, a hollowed out 3/8 threaded rod that I will pass the LED string wires through. The aluminum plug is threaded for this rod, and will act as a nut to tighten to once it's assembled.

Here is the windvane/emitter section assembled... Note the hollow threaded rod keeping it all together and the new recess in the aluminum plug that keeps it straight and tight.

Emitter end. The step down is to secure up into the blade to allow the metal to come up a bit past where the internal diffuser plastic tube is.

Just about right, as far as I can tell, on spacing for the emitter to windvane neck. I will drill and tap for screws here forward of the weathring line on the emitter section, these screws will completely solidify the blade, neck, plug, etc.

This site is part of the nonentity network. Not associated with LUCASFILM LTD.™ or any LFL Ltd.™ Film or Franchise.