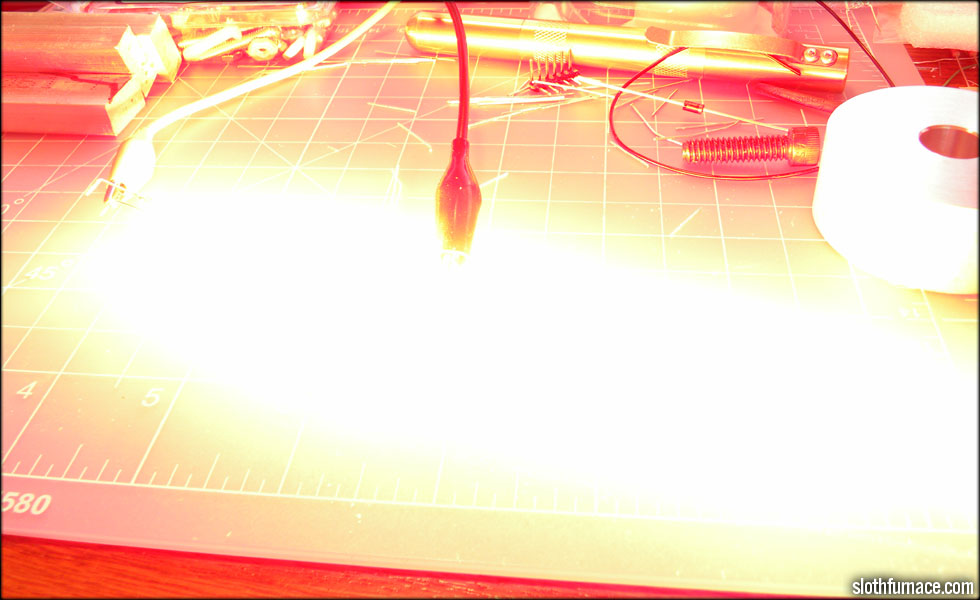

And here's a test of the superbright red LED string segment...

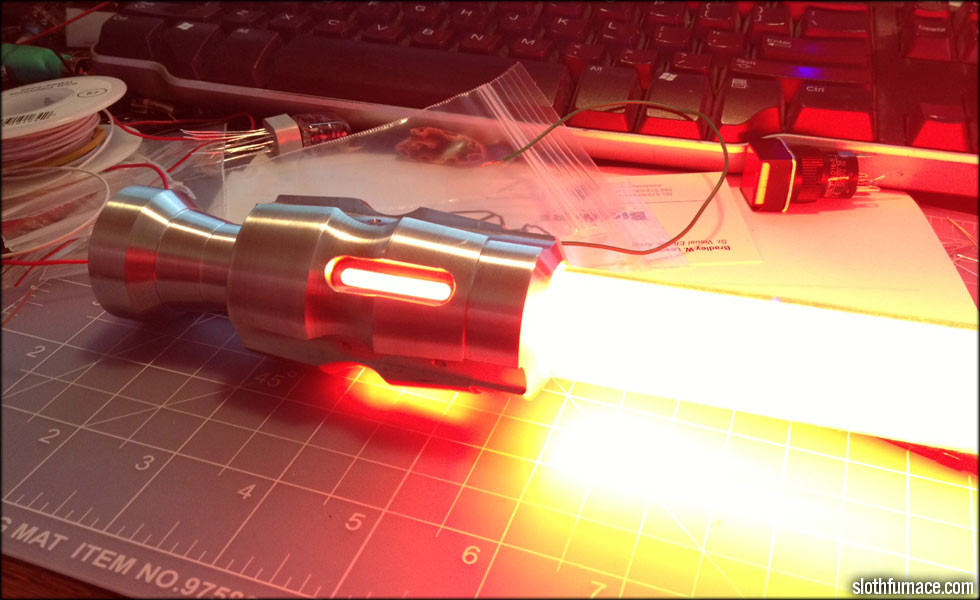

And a test of the light coming through the emitter windows.

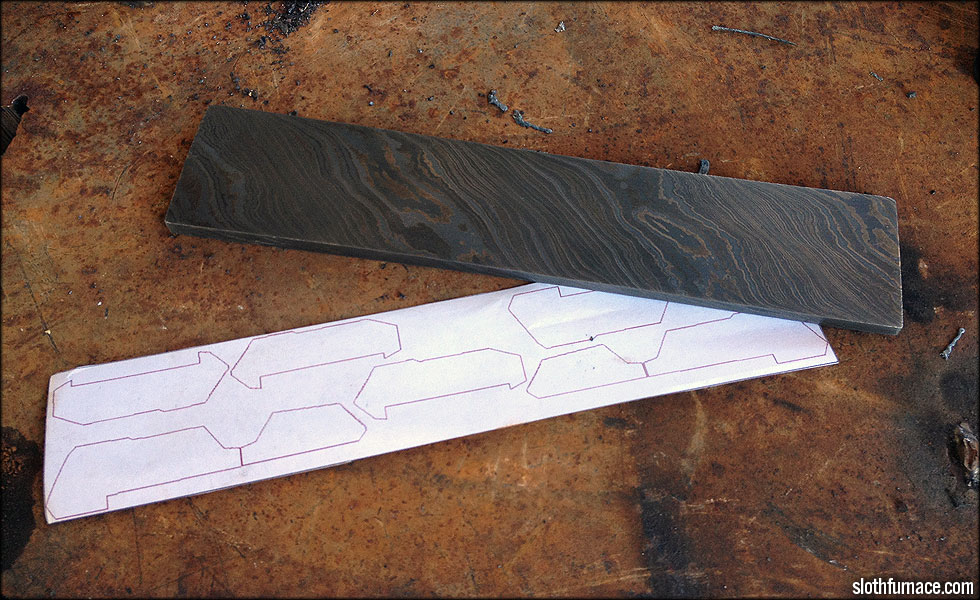

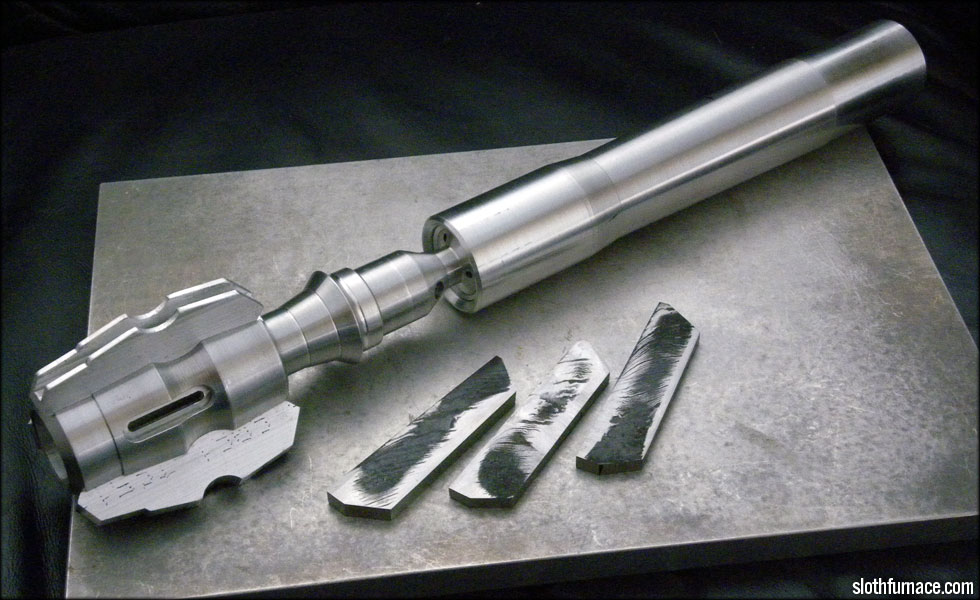

So here I have the Damascus billet. I need to break this down into smaller pieces so I can shape it up and get it installed in the fin slots.

However, it's pretty hard stuff, and I can't exactly chew it into shape, so I brought it down to the ranch to use Dad's plasma cutter.

And the first three chunks broken down. I'll clean the slag off and get em cleaned up once I get them back to the garage.

Kind of like this... these things are still too hard to machine even after I annealed them. However, my belt sander still works. It's slow, but will work.

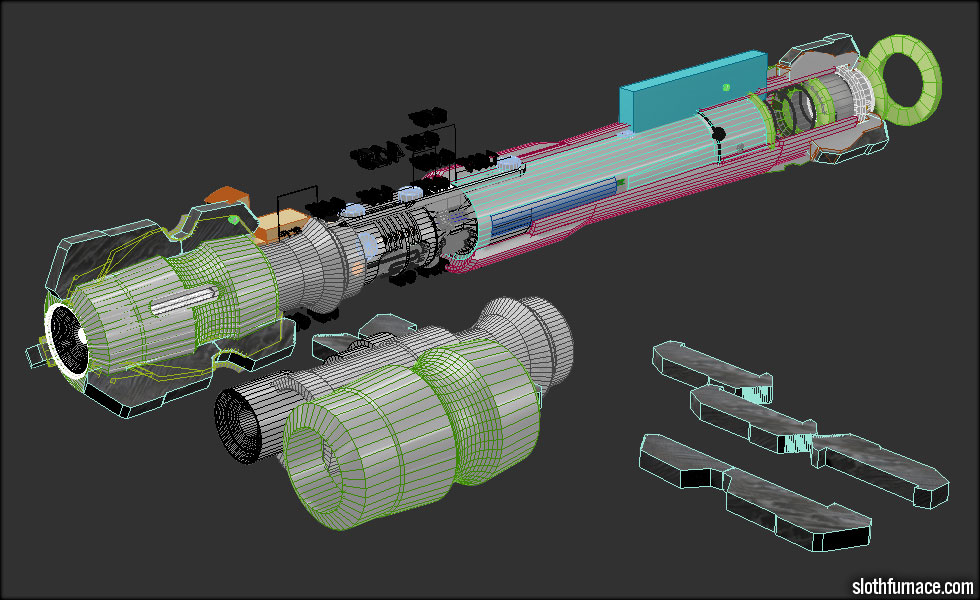

Working this saber design over in 3D is a big help for something this complicated. I normally just try to keep track of things in my head, but laying all the moving parts out in 3D before I cut metal sure helps.

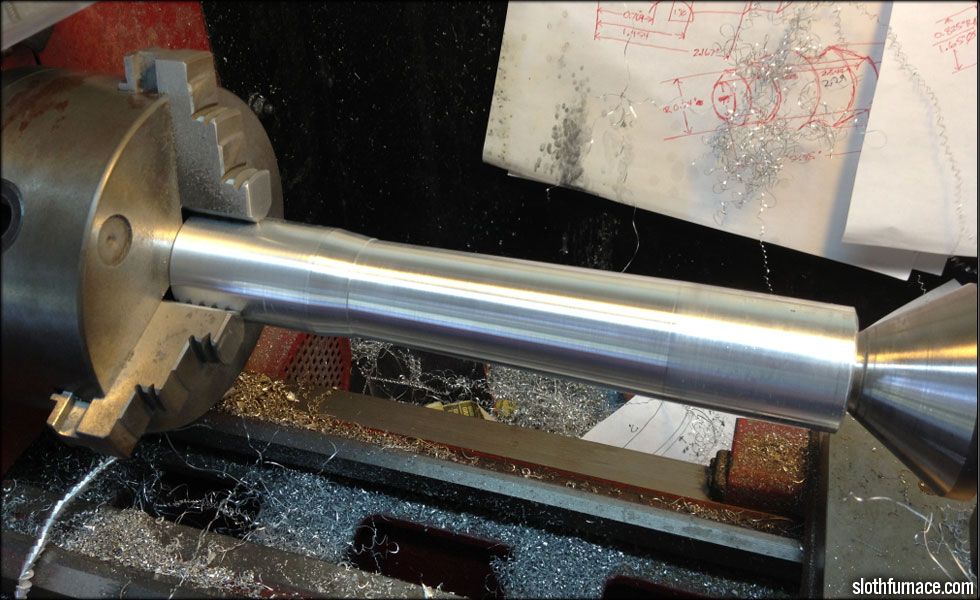

At this point, I think I am ready to storm into the garage and machine out the hilt shell. I have to get the subtle taper in there, and get it ready for boring out.

Boring the hilt shell for the sled piston is one of the tougher steps of this build, as I don't have a steady rest, or a boring bar long enough to go through the entire thing.

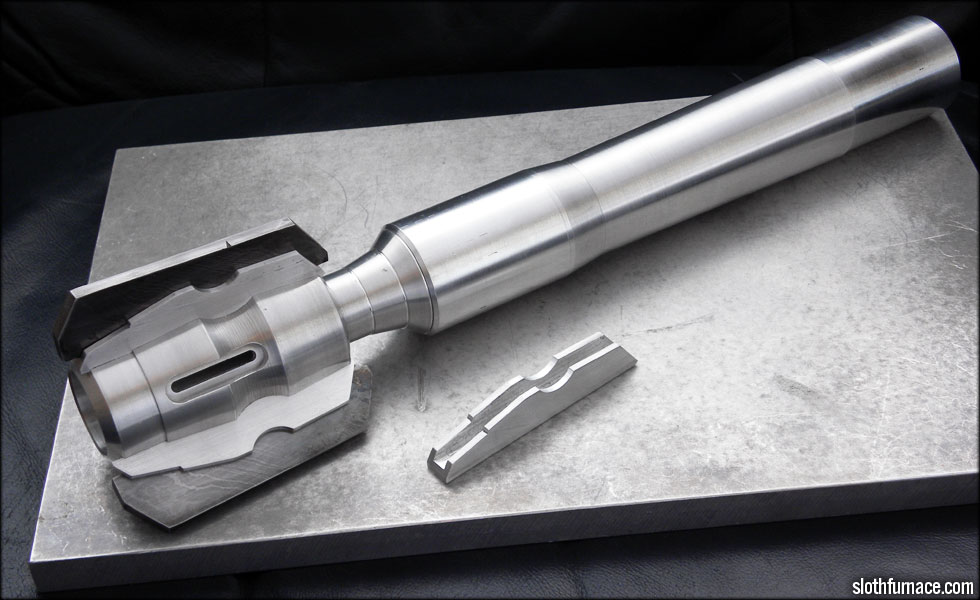

The parts stack at this point consists of the hilt shell, the sled piston, the neck, emitter head and bladeholder, fins, Damascus inlays, etc.

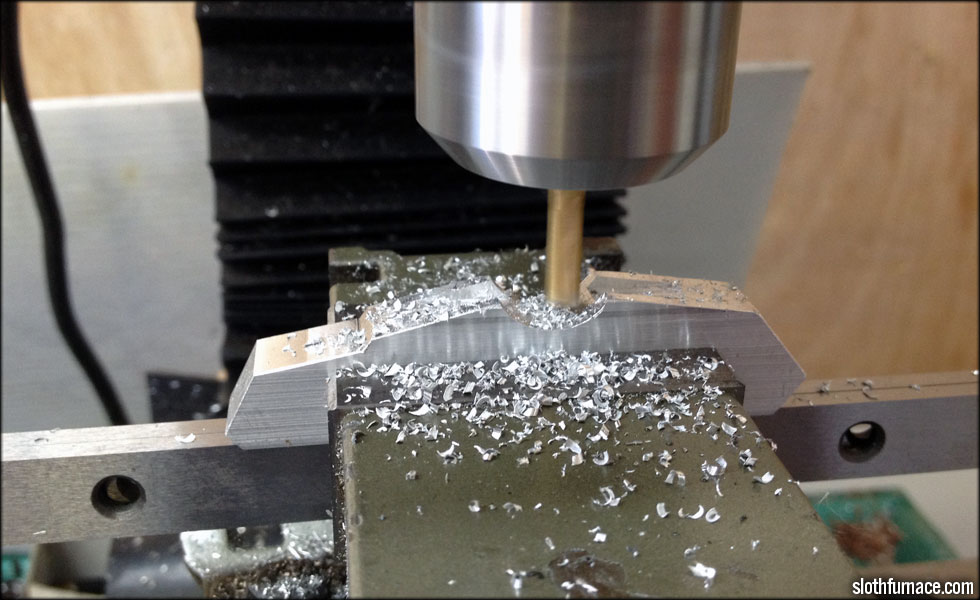

Speaking of the Damascus inlays, here I am cutting a slot in one of the fin bases for the Damascus.

I spent a few hours boring out the other end of the hilt shell, as I only have a boring bar half the length of my hilt, I had to do the inner bore in two passes. Using my dial indicator to make sure I was no more than a half thousandth off axis (best I could get) I went ahead and bored the other side to meet up with the original cut.

It ended up being perfectly smooth, and the axes of the two ends were closer than I could have expected. The sled piston moves smoothly with no wiggle, and as the unit opens and closes, it's a very satisfying click and slide.

Next up some emitter fin work, and I really need to work on the chamber. I need to cut it in half and thread it for the support rods and chamber fins.

This site is part of the nonentity network. Not associated with LUCASFILM LTD.™ or any LFL Ltd.™ Film or Franchise.