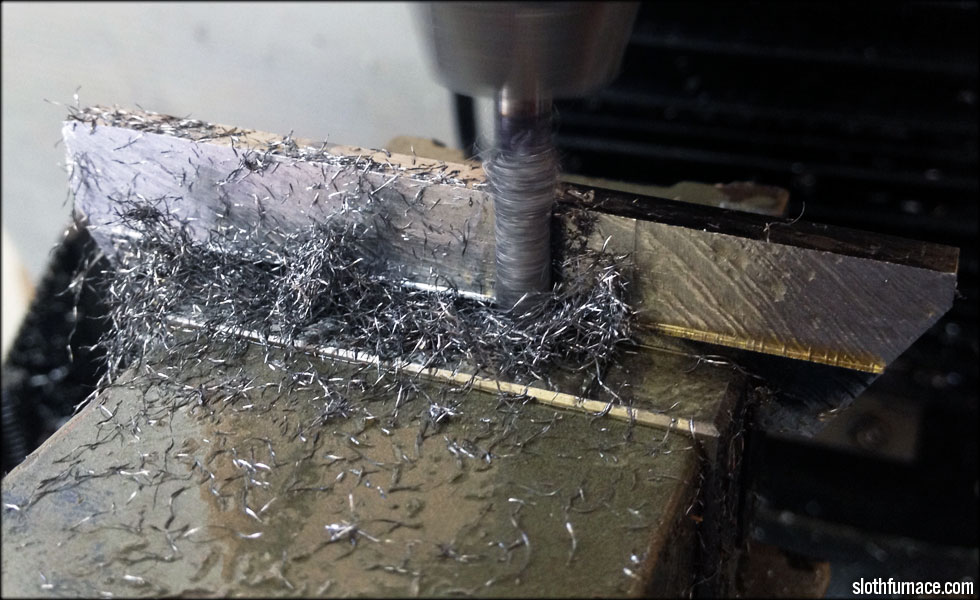

One of the most challenging materials I have ever worked in, and one reason this project has taken me so long, is this damascus steel. I believe this metal was originally made for knife blades, and it's very, very hard to cut. Here I am taking about all day to mill one fin down to the proper thickness.

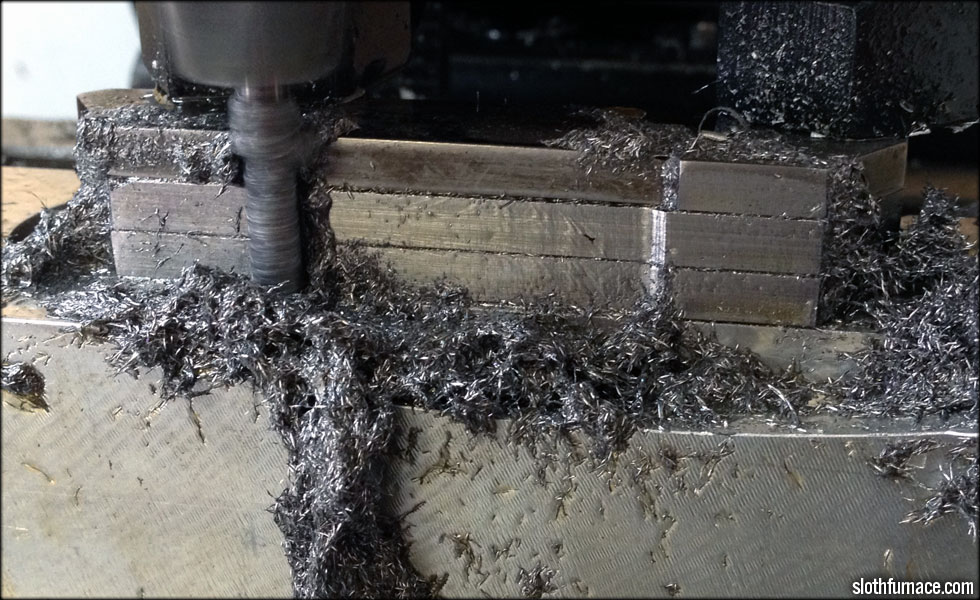

This cut to profile the top of the emitter fin inlays took all day as well. A couple thousandths of an inch at a time, with the feed set very slowly.

Here I have the profiles cut, and am testing etching and bluing methods to find the right combination of acid, bluing chemical, etc. to get the look I am working towards. These fins are a nice color, but only in certain light. I want more contrast, so back in to the acid they go...

And that's what I am looking for. A much longer acid bath, then wash with water and brushed with bluing chemical, and a light polish with find grit sandpaper, and I think I have what I am looking for.

They now contrast nicely with the aluminum fin saddles, and I think that's enought experimentation.

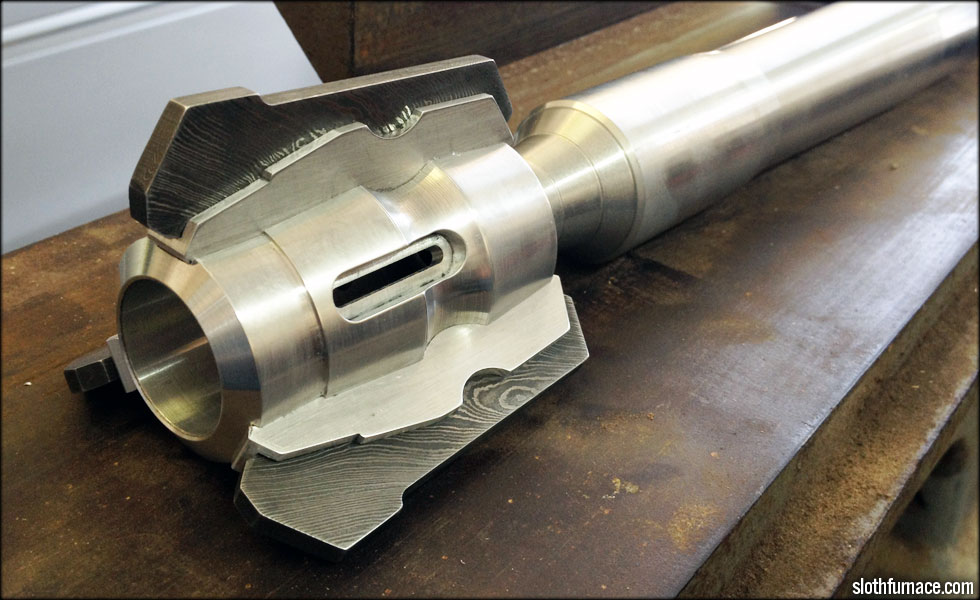

Here I am starting the pommel, machining the pommel blank out of a solid rod.

Pommel blank bored out to fit the back end of the hilt handle.

It's a very close fit. Pressed on, it has no wiggle room.

Next up, I'll be machining the pommel further to allow for the pommel fins.

This site is part of the nonentity network. Not associated with LUCASFILM LTD.™ or any LFL Ltd.™ Film or Franchise.