Here I am hollowing out the blade holder to 7/8, and I'll go the rest of the way to one inch diameter with a finer tool to control accuracy.

Here I am hollowing out the center portion to 3/8 for my DIN plug.

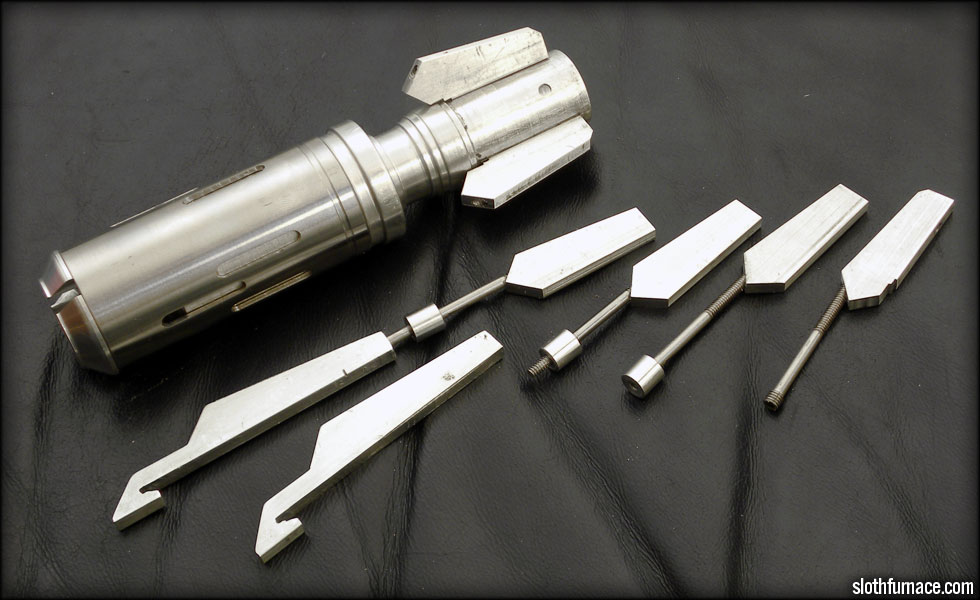

So I had to come up with a way to tighten the fin against the anchor. If I made the strut a solid piece, as I tightened it, one side would tighten, and one side would loosen. Since I can't reverse thread this piece, I came up with a solution.

inside the large cylinder is a freespinning bolt, the one going toward the fin. As I tighten that cylinder, the bolt going towards the anchor tightens, and lets the other bolt spin, or stay in place. This way I can tighten my strut. To do this, I took These stainless hex screws, thinned the head down and threaded it. This picture shows a 1/4 x 20 threading, but I ended up going with 10-32

And here is one test strut.. When I twist the outer ring, it tightens, and pulls the fin towards the anchor. The long hex screw is going toward the anchor, and has its head threaded to go into the cylinder. The other screw is just held in place by the smaller diameter end, kind of like a tall washer with bigger threads on the other end to accept the hex screw. This is a much more elegant design than I orginally had.

I got the metal in for the anchor pieces, and drew out the piece. I think I can get two per slab, if I cut it right.

Here I have three anchor pieces clamped together to mill at once. I will mill what corners I need to then hacksaw the majority of the metal away.

Like this. I think by doing this I won't waste any metal, as I can make six anchor pieces from cutting these in half.

And here I am milling out the slots for the anchor pieces. This would have taken so long without the mill. Now it takes minutes instead of hours.

This is how I will attach each fin anchor piece to the emitter neck. I drill a small hole for the screw to go through, drill and tap the anchor, and drill a large hole so I can fit a screwdriver through the opposite side and into the screw. I'll need to do this three times, and on one side mill out a slot for the on off switch housing.

Here I have the strut assembled. I think I'll have to tweak some lengths on some things, but it should work fine. What I don't like about it is the small patch of exposed threads on the sloped face of the anchor piece, and that the hole I drilled for the strut to thread into popped out of the top of the anchor a wee bit. Oh well, "battle damage."

Here's the emitter neck and anchor fit into the slot I milled out of the handle. It's a nice snug fit. I did have to file the round area where my milling bit stopped so that it was square, but that's why I keep some files around.

Shaping up, I need to run to the hardware store to pick up some screws and material to do the other 5 struts. Three on each end. The saber parts are getting kind of scratched up, but I'll buff everything out before I am done.

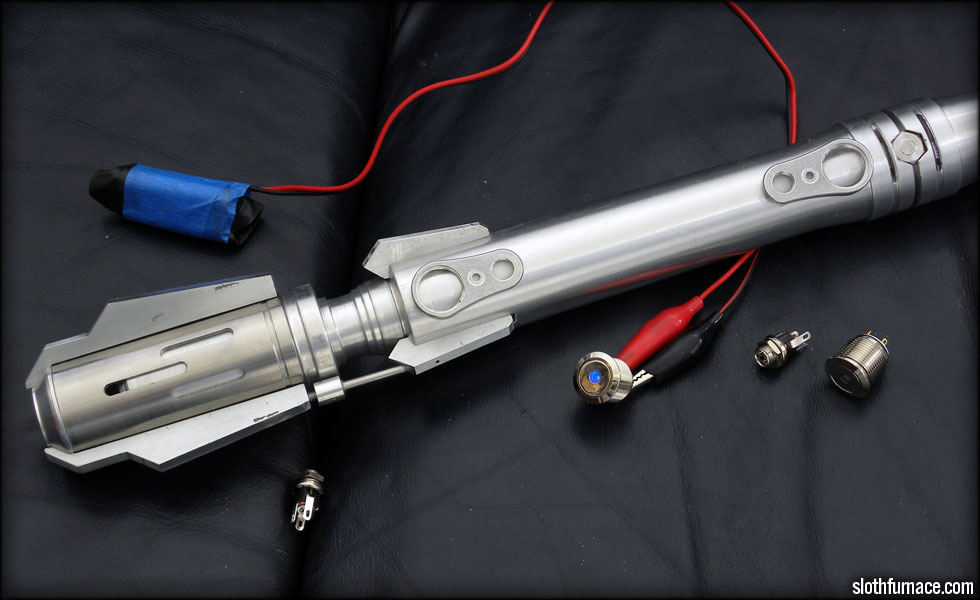

One thing that's been holding me up on this saber is the main switch. I haven't been able to machine anything that perfectly matches the switch bezels for this saber, but TCSS offeres these new switch bezels that are pretty close, and might work with a bit of modification. I asked the wife if she liked them, and she said she does, so these might be my solution paired with the blue dot AV Switch. One for activation at the center, one for aux button at the emitter end.

While I am deciding on the switches, I went ahead and started using my mill and milling vise to cut the other set of fin anchors. WOW this is so much easier than using a hacksaw and set of files.

Now I have six, three perfectly identical, I might go ahead and mill out three more just to have a nice set of nine to pick the best from.

FINALLY got the other slots milled in the grip of the other saber, now I can drill, tap threads in the fin anchors on the other side, and assemble those pieces. I still have the rest of the fin struts to make, and to bevel the tail ends of the new fin anchors.

Couldn't resist putting a couple blades in there to see what it looks like, this thing is LONG. I haven't decided what length of blades to go with yet, but I'll probably go shorter than what I have in there now. I think they're 34 inch blades currently.

I always snap everything back together when I am done for the day so it will taunt me from the corner of the room saying "come work on me, you know you want to."

I took a 5/8 ballnose endmill and bored out a hole for the switch back to sit in.

The button and bezel are just laying in there now, I'll have to widen the hole just a tad to get it to line up with my centerline. I have wiggle room enough for that though.

This site is part of the nonentity network. Not associated with LUCASFILM LTD.™ or any LFL Ltd.™ Film or Franchise.