The Homage Blade Plug will be a miniaturized version of my first crystal chamber reveal, which firmly got me started in this hobby.

My ANH Luke Epic reveal saber was the first in the lightsaber community to use fin and rod radiator style fins, it was approved by Lucasfilm for SWTOR as the inside of a lightsaber, and it launched my saber building career.

And here is where I will start with this project. I need to replicate in miniature the chassis fins from my ANH Luke reveal. And since I've learned a bit in the more than ten years since I did that build, I will be documenting the new process here.

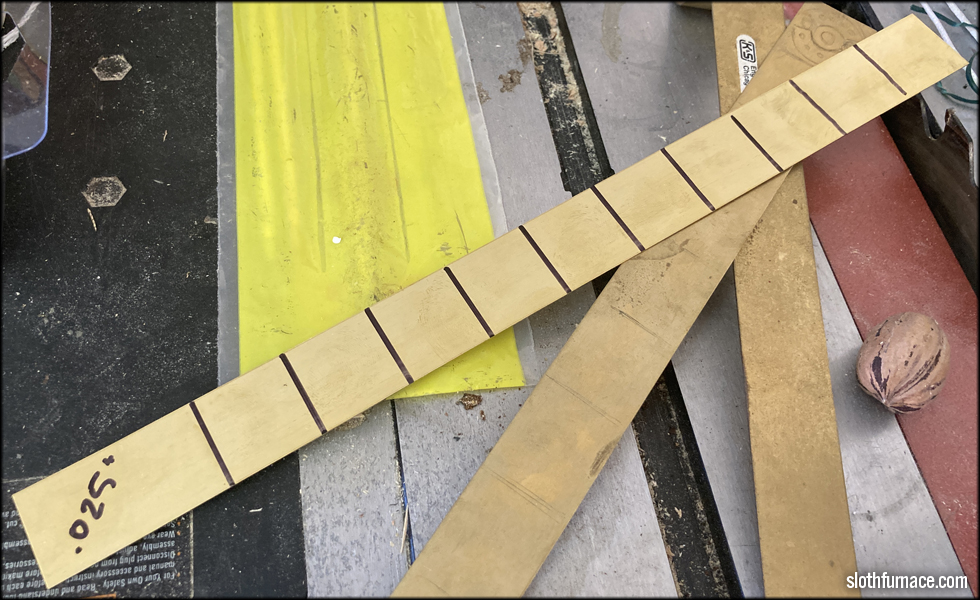

I selected a 1 foot by 1 inch strip of 0.025" thick brass stock, and marked it off in one inch sections where I'll make my cuts. Pecan for scale.

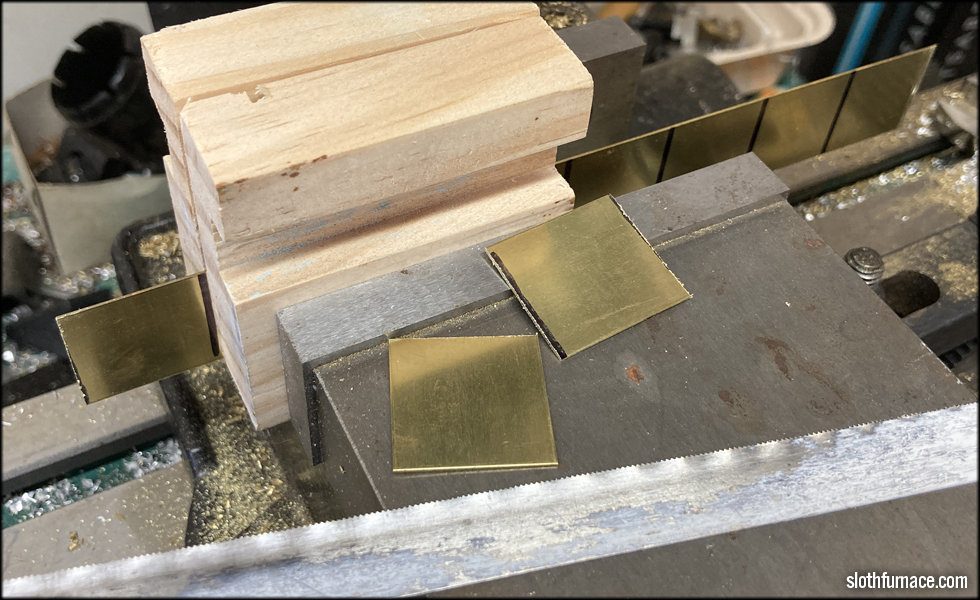

I clamped this in the vise, between two wooden blocks, and began the long process of hacksawing the fin plates from the strip. I go very slow and carefully here since I do not want to bend or warp the brass in any way.

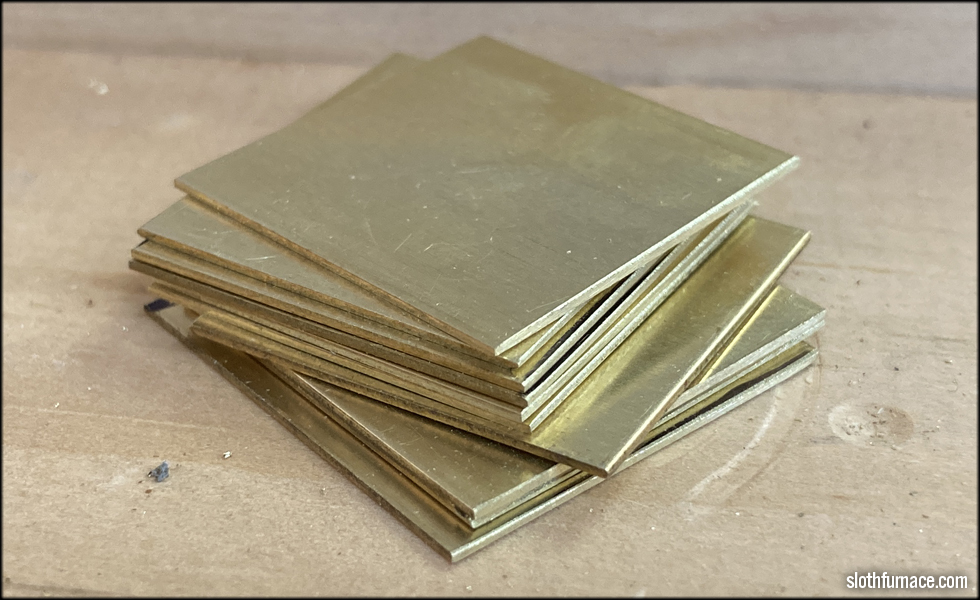

This left me ten or so one inch square plates of brass, but with burred and rough edges.

A quick deburring operation with some 220 grit sandpaper on a sanding block for each ond and I am left with a nice clean stack.

These are ready for the next operation.

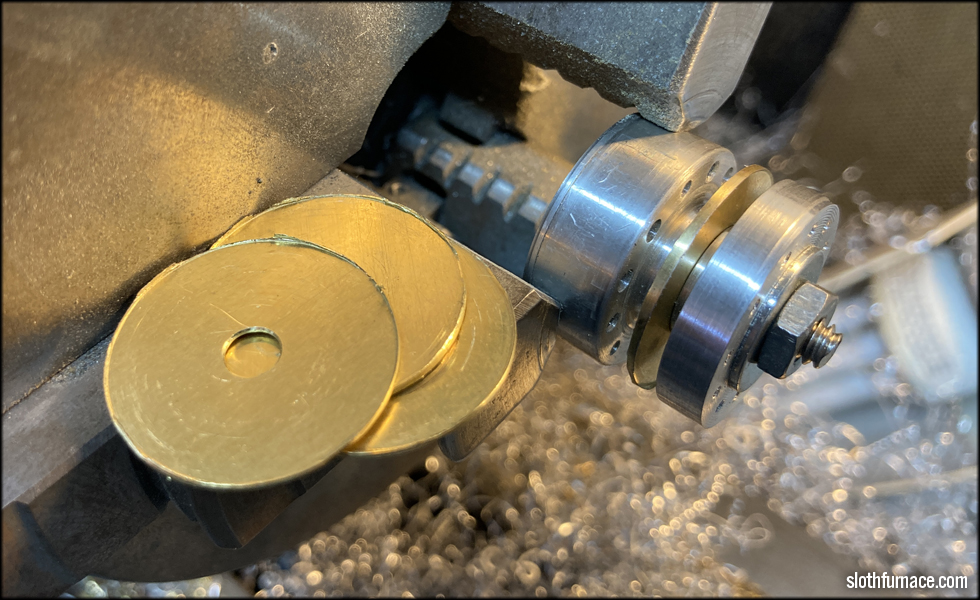

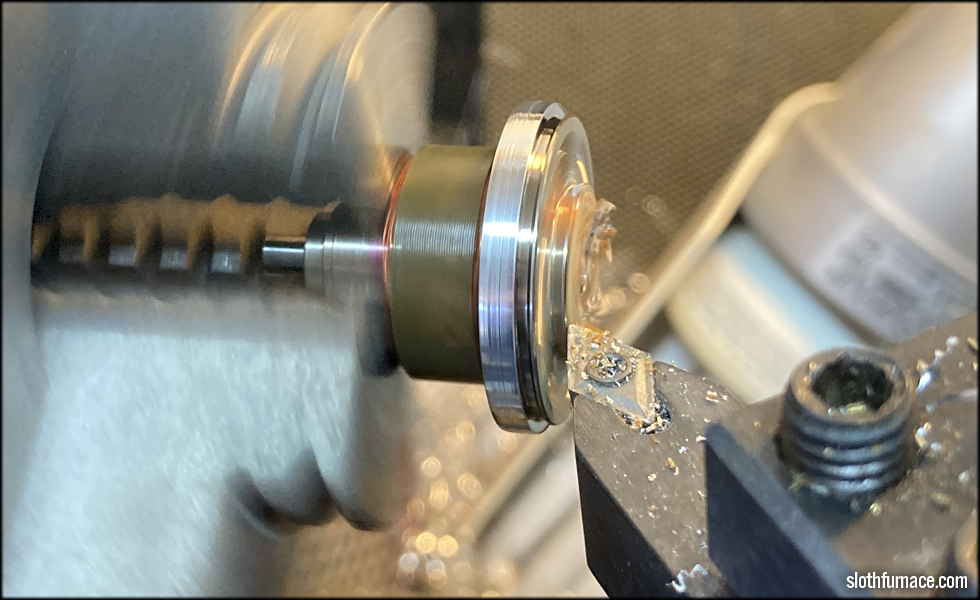

At this point I actually had to come up with a good way to cut these into discs without warping them on the lathe. At first I drilled a hole for a 6-32 threaded rod in the center of each plate, and strung them up on a rod on the lathe. One end in the chuck, and one end spinning in a brass tube in the tailstock chuck to keep the whole thing from deflecting as I cut. However, this proved to flex too much on the 6-32 rod, so I abandoned this setup in favor of the way that I stuck with for the rest of the plates.

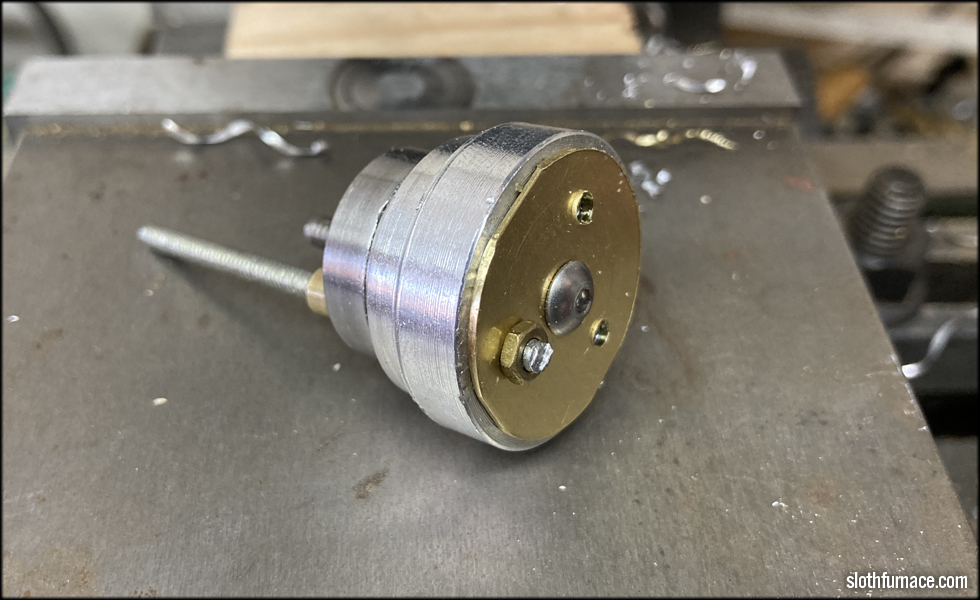

These plates are clamped between two harddrive motor housings to keep the edges from deflecting and bending under the cutting tool, and all on a 10-32 threaded rod/bolt. The process was rough, and chattery, but eventually I got them cut down to uniform discs, but not without a sharp, burred edge.

Which I dealt with by flipping my hard drive motor housings 180 degrees on the rod and, one at a time, deburring and polishing each disc to a more consistent shape and finish.

As shown here, they look like little gold records when they're done.

I had made a 3 hole jig to align and keep consistent my mounting holes for the fins, and to transfer those holes to any other part I would be using for the chamber, and that's how I got the holes for the fins in the right spot, by using this guide. Which, when I'm all done with this, may even use as parts of the chamber itself.

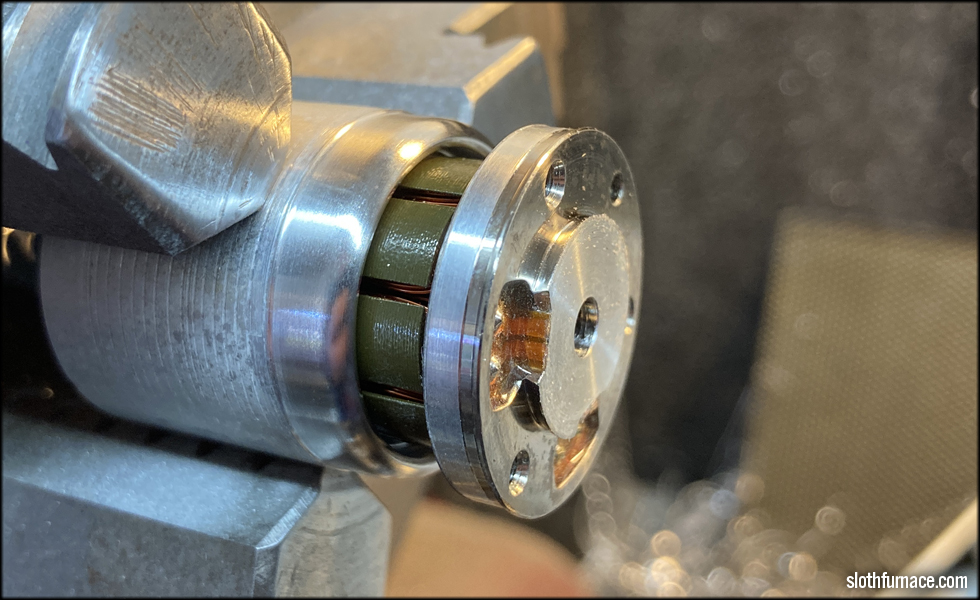

Speaking of the rest of the chamber, I needed a base for the pixel connector and a top for the emitter end. So I went back to my original pile of parts I used for my ANH Luke chamber, and selected one of the hard drive motor coils I didn't use. I punched the bearing out just enough so I could get it into my lathe chuck, and then turned the outer diameter down to one inch, and cleaned the face.

For the "battery can section" of this blade plug, which won't house a battery, but will house the pixel connector, I chose some scrap one inch diameter aluminum.

I rounded the cowl and prepared to hollow it out to accept the motor coil section.

I may dress this cowl curve profile a bit before I'm done, but I like this for now.

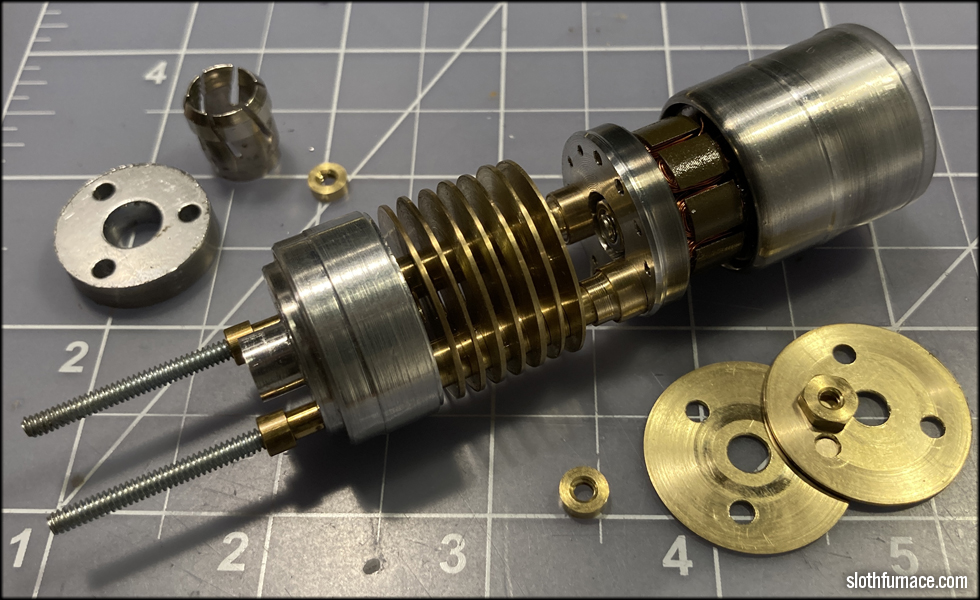

At some point, I took a handful of my vintage nicely machined 4-40 brass nuts and turned them down on the lathe to make them round instead of hexagonal for the spacers between the fins.

The pieces laid out for size and scale, and I have more fins than I need, just in case I mess one up. But the general idea is to replicate my 1.5 inch diameter ANH Luke crystal reveal chamber for this blade plug, as such I may go from nine plates in the chamber to seven or eight for this plug.

At this point it's beginning to come together, and I know what I'll do to light up the end. I'll machine a delrin core with a Graflex style plunger tip seated in a concave recess, all within a piece of polycarbonate for light diffusion.

This site is part of the nonentity network. Not associated with LUCASFILM LTD.™ or any LFL Ltd.™ Film or Franchise.