My brass for the crystal chamber finally arrived, and here I am cutting a radiused face into it for the crystal mount using my Holdridge Radius cutter mounted on my tool post on the lathe.

I need a new short cutting tool though, this one is chipped. But it will do for now.

I also drilled a temporary hole through the middle and concave radiused the inner corner.

Here I have an assortment of crystals to pick from for the chamber, I think I'll go with the top middle one.

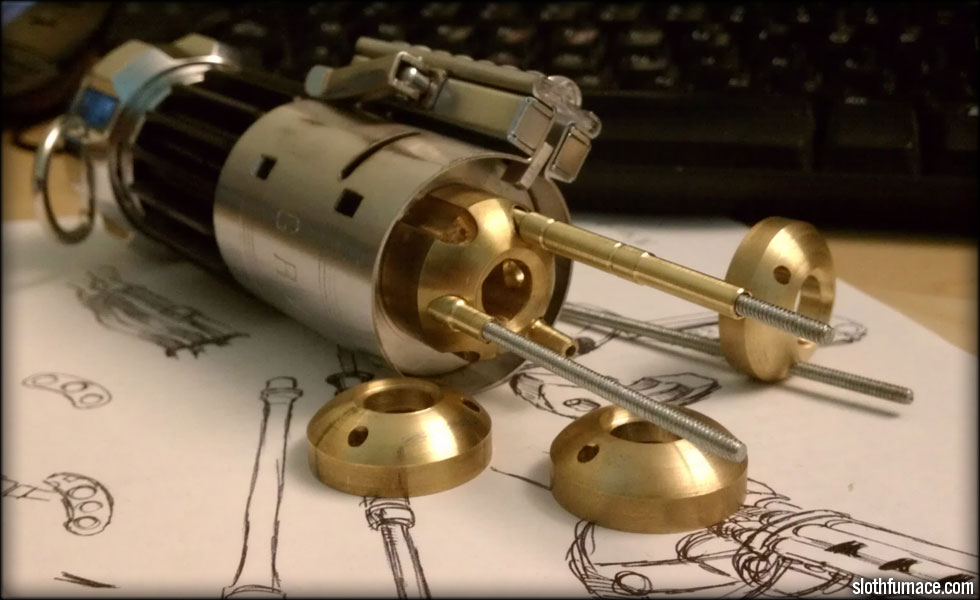

After an evening of milling, drilling and tapping, I got the three 4-40 support rods evenly spaced, the three LED holes set, and the channels for the wire. I also had to keyhole mill the slots for the crystal.

I'll probably do a lot more work on this, but I like where it's headed. I'll need holes for wire conduit, possibly some more decoration, but I do love the curved face of the mount.

Normally, I use flat plates to do my "radiator fins" for these crystal chambers. This time, I wanted to do something a little more challenging. I want to try making domed fins, carrying the curve from the crystal mount all the way through the chamber. To do this, I need to make several of these radiused blanks. It's a process that involves facing off the brass rod, using and endmill to cut my 3/8 internal hole, setting up the radius cutter, getting it in the right spot, making my concave radius, taking the radius cutter off the tool mount, setting up the part off tool, parting off the blank, facing off the back of the blank. Rinse and repeat four times (or more) and then I have to transfer my hole pattern from the crystal mount to the blank. Once I am done with that, I have to flip them all over and cut the convex radius in a process yet to be determined. It's tedious work, but I have a feeling it will pay off. Right now they're quite a bit thicker than I need, but that's to allow for working with them easier. It's really hard to chuck thin things up into my lathe. I'll need to make a radiusing jig to bolt each one to so I can get to it with the radius cutter.

My jig worked finally after a few revisions, and I was able to get inner and outer radius cuts on my fins. These will be pretty thick. I might thin them out afterwards, once I get more of the assembly done.

These won't go all the way around the chamber in the final build, I'll have a window cut into them so you can see the crystal, much like the other fins I have done. Next up, getting some brass tubing that fits the 4-40 threaded rod, and milling flats so the spacers fit flush into the fins.

Broke a 4-40 tap last night or I'd be further along on this. BUT I was able to drill out through the center of my brass rod, which was nice.

This site is part of the nonentity network. Not associated with LUCASFILM LTD.™ or any LFL Ltd.™ Film or Franchise.